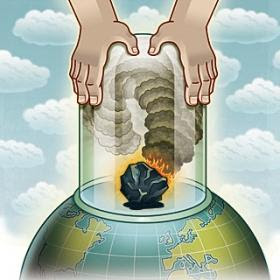

Can Captured Carbon Save Coal-Fired Power?

Extracting carbon dioxide from power plant exhaust and storing it underground may be the only hope to avoid a climate change catastrophe caused by burning fossil fuels

Like all big coal-fired power plants, the 1,600-mega-watt-capacity Schwarze Pumpe plant in Spremberg, Germany, is undeniably dirty. Yet a small addition to the facility—a tiny boiler that pipes 30 MW worth of steam to local industrial customers—represents a hope for salvation from the global climate-changing consequences of burning fossil fuels.

To heat that boiler, the damp, crumbly brown coal known as lignite—which is even more polluting than the harder black anthracite variety—burns in the presence of pure oxygen, releasing as waste both water vapor and that more notorious greenhouse gas, carbon dioxide (CO2). By condensing the water in a simple pipe, Vattenfall, the Swedish utility that owns the power plant, captures and isolates nearly 95 percent of the CO2 in a 99.7 percent pure form.

That CO2 is then compressed into a liquid and given to another company, Linde, for sale; potential users range from the makers of carbonated beverages, such as Coca-Cola, to oil firms that use it to flush more petroleum out of declining deposits. In principle, however, the CO2could also be pumped deep underground and locked safely away in specific rock formations for millennia.

From the International Energy Agency to the United Nations–sanctioned Intergovernmental Panel on Climate Change (IPCC), such carbon capture and storage (CCS), particularly for coal-fired power plants, has been identified as a technology critical to enabling deep, rapid cuts in greenhouse gas emissions. After all, coal burning is responsible for 40 percent of the 30 billion metric tons of CO2 emitted by human activity every year. “There is the potential for the U.S. and other countries to continue to rely on coal as a source of energy while at the same time protecting the climate from the massive greenhouse gas emissions associated with coal,” says Steve Caldwell, coordinator for regional climate change policy at the Pew Center onGlobal Climate Change, an Arlington, Va., think tank.

Even President Barack Obama has labeled the technology as important for “energy independence” and included $3.4 billion in the economic stimulus package for “clean coal” power plants. But although multiple projects around the world examine or test aspects of CCS, few of them have been connected to a full-size power plant: one producing on average 500 MW and upward of 10,000 metric tons of carbon dioxide a day—the core of the emissions problem.

“It makes nine metric tons of CO2 per hour at full load,” says Staffan Görtz, Vattenfall’s CCS spokesperson, of the $100-million CCS demonstration boiler at Schwarze Pumpe. But he acknowledges that “we don’t have a storage site yet.”

Buried at Sea Storage may be the simplest part of the CCS challenge. After all, since 1996, the Norwegian oil company StatoilHydro has been stripping CO2 out of natural gas from the Sleipner field in the North Sea and rather than venting it to the atmosphere has been pumping it back into the field 1,000 meters deep for permanent storage.

The basics of carbon dioxide storage are simple: the same Utsira sandstone formation that has stored the natural gas for millions of years can serve to trap the CO2, explains Olav Kaarstad, CCS adviser at Statoil. The 250-meter-thick band of sandstone—porous, crumbly rock that traps the gas in the minute spaces between its particles—is topped by a relatively impermeable 200-meter-thick layer of shale and mudstone (think hardened clay). “We aren’t really much worried about the integrity of the seal and whether the CO2 will stay down there over many hundreds of years,” Kaarstad says.

More than 12 million metric tons of CO2 have been injected into the formation, he notes. Statoil monitors its storage through periodic seismic testing, a process that is not unlike a sonogram through the earth, according to hydrologist Sally Benson, director of the global climate and energy project at Stanford University. That monitoring indicates that between 1996 and this past March, the liquid CO2 has spread out as a thin layer permeating a three-square-kilometer expanse of porous sandstone—just 0.0001 percent of the area available for such storage.

Comments